UNIFORM LABEL SYSTEM

Design & Production System

Visual Systems • Production Design

Role

Visual Designer (Lead)

Team

Creative Director

Output

Multi-client uniform label system (main, size, care, packaging) + production-ready files

OVERVIEW

Small components, high operational and brand impact

Uniform labels are a required component of every uniform program, encompassing main, size, care, and packaging labels. I owned this system end to end — rebuilding and standardizing the label framework, designing labels for new clients, maintaining existing programs, and delivering production-ready files to manufacturers.

While small in scale, labels play a critical role in brand consistency, production accuracy, and overall uniform cohesion. This work highlights how a standardized, reusable label system supported multiple clients and uniform collections while balancing visual clarity with operational efficiency.

CHALLENGE & CONTEXT

Fragmented label programs limited scalability and production efficiency

Each client brought distinct brand guidelines that labels needed to follow while remaining legible, durable, and functional on fabric.

The label system required rebuilding and standardization to reliably support production, reorders, and new uniform launches. The work extended beyond new label design to include reorganizing fragmented files, updating outdated layouts, and establishing a clear structure that could scale across clients.

The challenges varied by client stage:

New clients required complete label systems to be designed from scratch, aligned with both brand standards and internal production requirements.

Existing clients required updates, reorganization, and ongoing maintenance to ensure accuracy and efficiency.

There was also an opportunity to reduce cost and production time by reusing pre-approved label structures across programs, while establishing a consistent, company-specific label style that reinforced studio standards.

APPROACH

Designed a flexible label framework that balanced brand needs and production realities

The label system was built to support multiple garment constructions while maintaining consistency across clients and collections. Rather than treating labels as one-off deliverables, the work focused on creating reusable structures that could scale across programs.

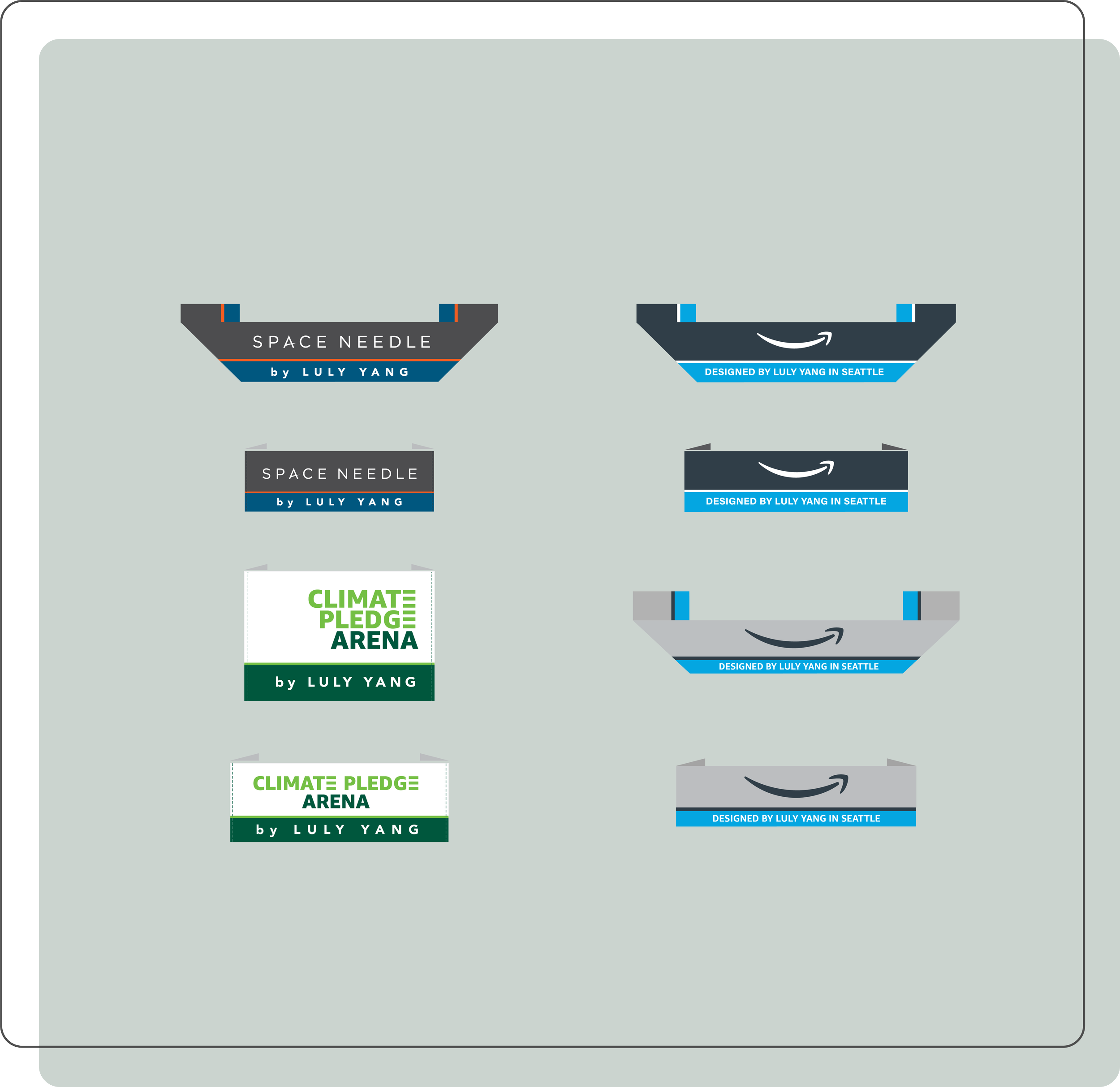

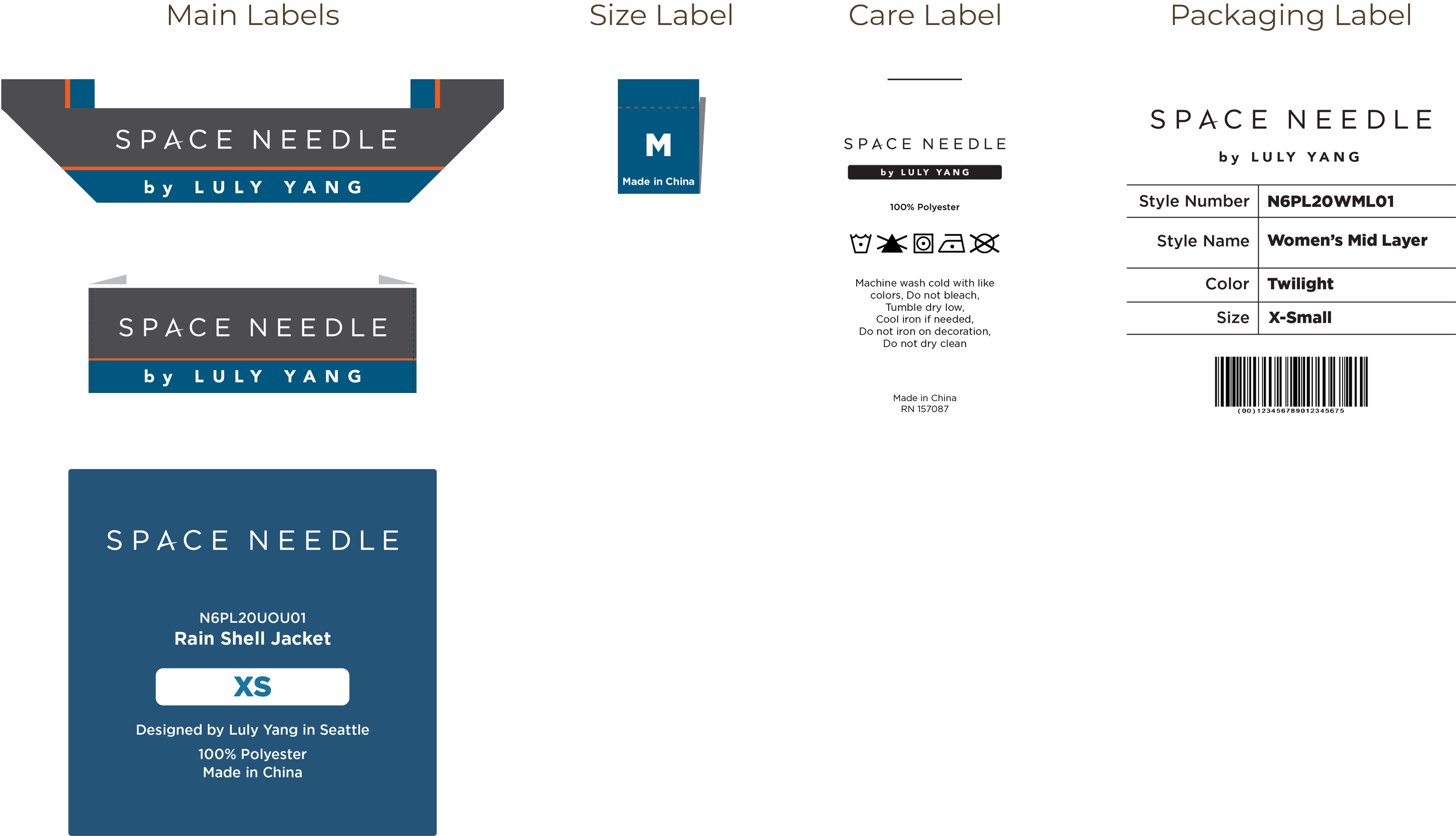

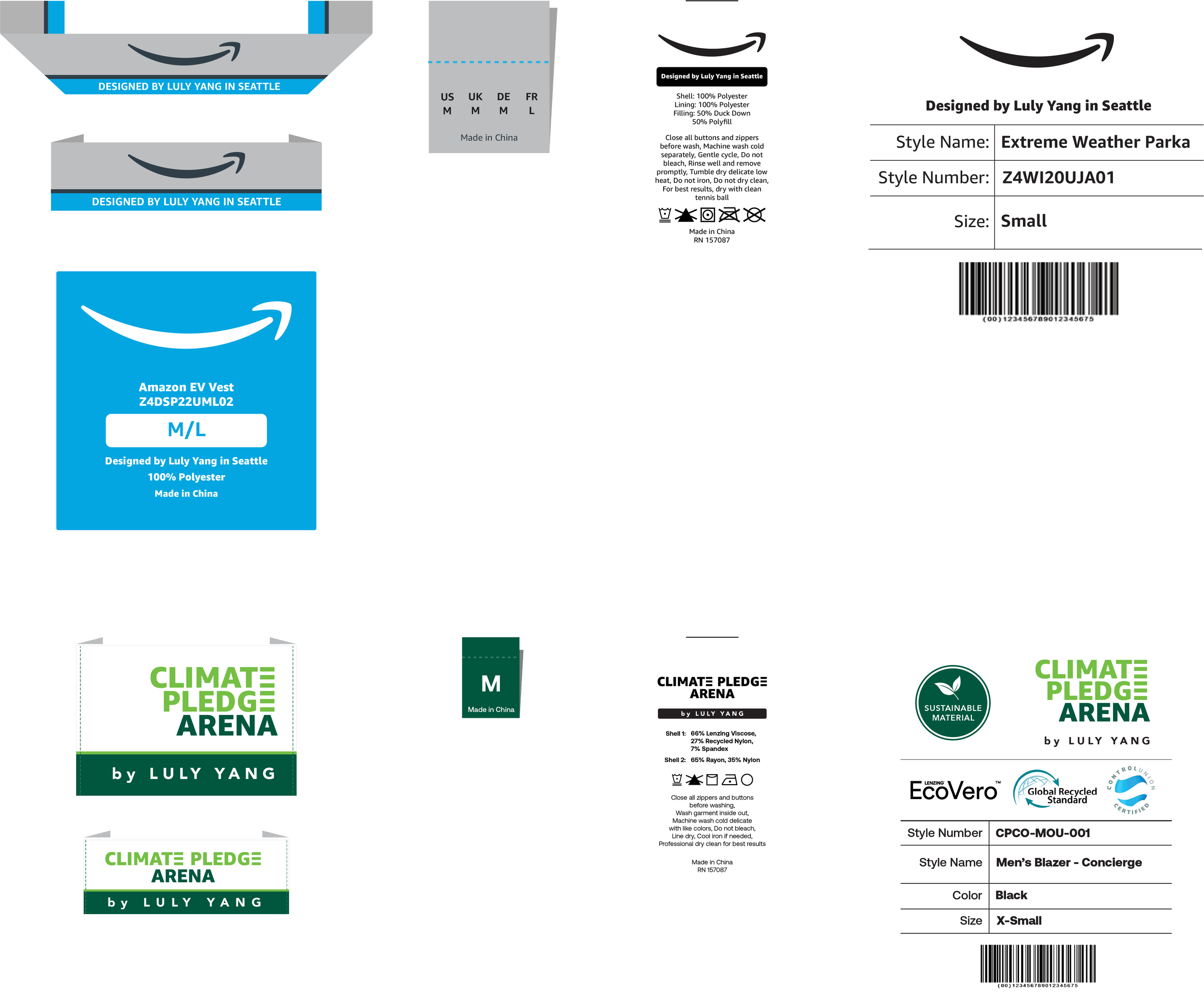

The system centered on four core components — main, size, care, and packaging — standardized for readability, durability, and manufacturing accuracy.

Key principles guided the approach:

Modular structure

Built flexible label frameworks that adapted by client, garment type, application method, and region of use (U.S. vs. global programs), while maintaining consistent hierarchy and layout rules.Brand flexibility within constraints

Adapted typography, color, and logo usage per client without altering underlying structure.Reusable foundations

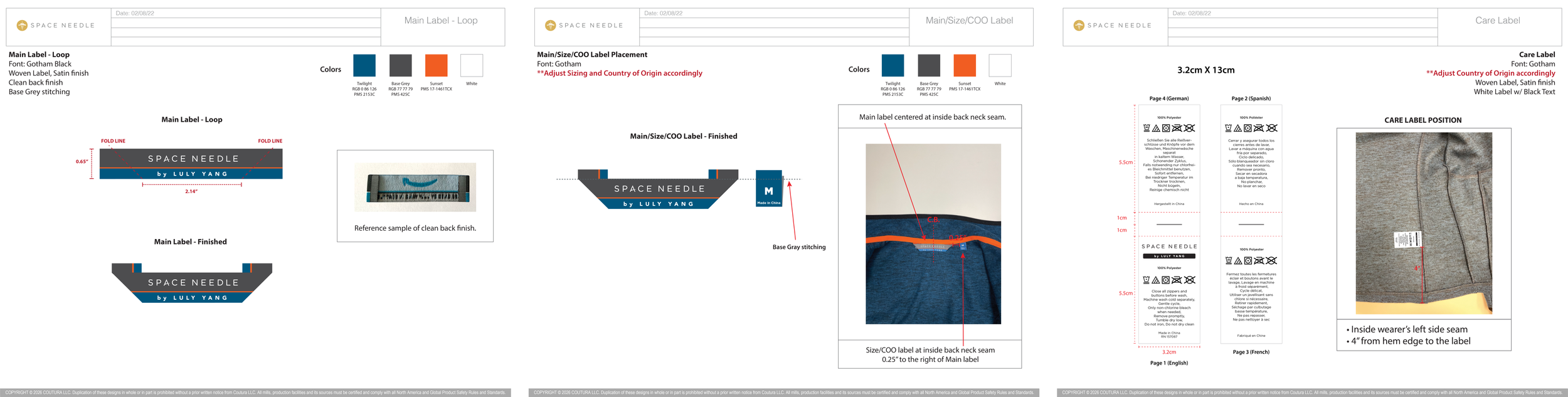

Leveraged pre-approved formats to reduce redesign, shorten approval cycles, and support faster onboarding.Standardized tech pack framework

Established a consistent tech pack layout and formatting standard for all labels, replacing fragmented legacy formats and improving clarity for manufacturer handoff.

The same underlying structure scaled across clients through controlled brand variations.

This framework enabled efficient scaling across clients while maintaining visual cohesion and operational clarity.

ROLE & OWNERSHIP

Led end-to-end execution across design, system maintenance, and production

I owned the uniform label system from initial rebuild through ongoing label production support, spanning both hands-on design and long-term system stewardship.

Scope of ownership included:

System rebuild & standardization

Consolidated fragmented legacy files into a centralized, scalable label library.Label design & implementation

Designed and launched complete label systems for new clients, establishing initial structures, layouts, and production-ready files.Ongoing maintenance

Maintained existing label programs through revisions, reorders, and new garment additions while preserving system consistency.Production file preparation

Created production-ready artwork, tech packs, and placement references for manufacturer handoff.Manufacturer coordination & approvals

Reviewed and approved all label artwork for production, coordinating directly with manufacturers to resolve questions and ensure accuracy prior to manufacturing.

This ownership model supported fast updates, reliable reorders, and consistent execution across uniform programs.

IMPACT

Improved accuracy, reduced cost, and accelerated production timelines

Standardized tech pack layouts enabled consistent manufacturer handoff and reduced production errors.

Streamlined production workflows, reducing errors and improving turnaround for new and repeat orders.

Lowered manufacturing costs through reuse of pre-approved label layouts with updated content.

Maintained consistent branding across multiple clients and uniform collections.

Established a reusable, company-specific label style that reinforced studio identity.

Created and maintained a centralized, scalable label system supporting fast updates, reorders, and production handoffs.